|

|

|

|

|

|

The Industrial Heritage Group

Leader: Mike Stow - indhist@ashbyu3a.co.uk - phone 01530 469152

The Industrial Heritage Group is for members who have an interest in our industrial heritage of trains, cars, planes, bikes, early manufacturing etc. to visit museums, railways, factories and other places related to our industrial past. We occasionally take a quite broad view of what constitutes "Industrial Heritage" if it is of interest to us!

Travel arrangements vary depending on how far we have to travel, but generally we meet in Ashby to car-share.

Our trips are normally on Wednesdays unless otherwise stated.

All dates below are provisional until stated otherwise

Future programme | ||||

| Date | Time | Venue | Organiser | Details |

| Wed 25th Feb | TBA | Mountsorrel Heritage Centre | Bob Baxendale | |

| Wed 25th Mar | TBA | TBA | ||

| Wed 22nd Apr | TBA | Lichfield Cathedral | ||

| Wed 27th May | TBA | Mini Factory tour | Mike | |

| Wed 24th Jun | TBA | Churnet Valley Railway | Colin | |

| Wed 22nd Jul | TBA | Frogmore Paper Mill | Bill Wilson | |

| Wed 26th Aug | TBA | TBA | ||

| Wed 23rd Sep | TBA | Ironbridge Valley museums | ||

| Wed 28th Oct | TBA | Acme whistles factory tour, Birmingham | Kurt | |

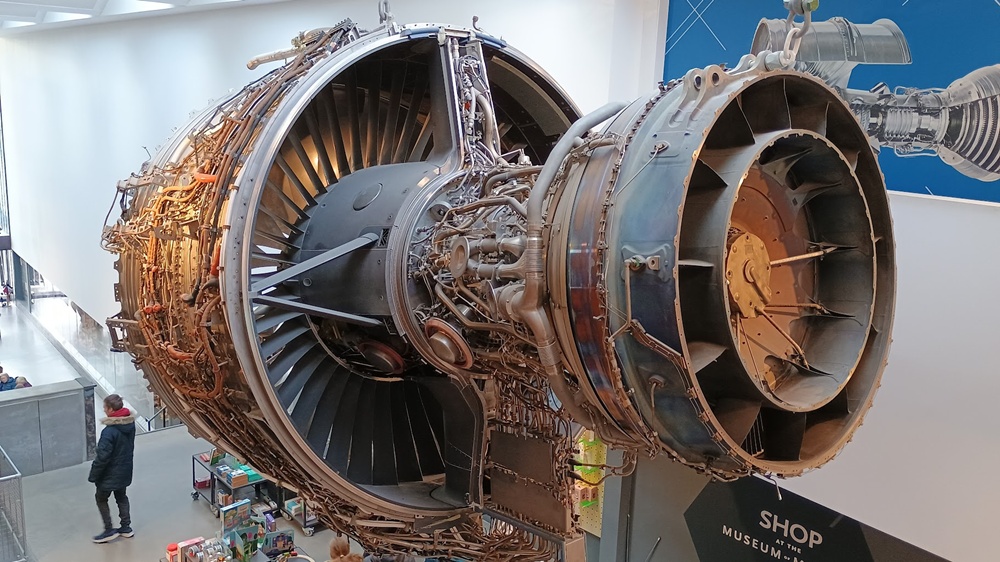

Wednesday 28th January. A visit to Derby Museum of Making

The weather was kind to us on Wednesday and the rain held off all day making the journey and the 10 min walk from the car park a lot easier. Talking of the car park, just about every utility company is digging up the roads around the area making it difficult to access the CP and when we did get in we found it to be almost full. And the meters only take cash (no change given!) or a phone app which nobody seemed able to access. Much scrabbling around for loose change ensued. Just as well it wasn’t pouring with rain as it took us ages to buy the tickets. The pathways to the museum were also being dug up and the river Derwent was in full spate.

Once we got to the museum things were much better. After a well deserved cuppa, we set off to wander around. The excellent model railway was running which kept everyone amused for a while. The museum houses samples of just about anything made in Derby. The obvious things are to do with the railways, Rolls Royce aero engines and Toyota cars, but Derby factories have made so much more. The amount of ‘stuff’ on display is amazing. Much of it is the detritus which would have been thrown away when firms closed down, but it is all so fascinating. From model trains and aero engines to tin plate and cast iron signage, to wooden moulds used for making cast iron parts to ledgers and tools plus everything from oil lamps to lawnmowers. There is a collection of clothes made locally, pottery and chinaware, motorbikes and bicycles. Clocks and mining equipment, stonemasonry and maps. There is even one of the original RR aero engines from Alcock and Brown’s Vickers Vimy. The first plane to cross the Atlantic non-stop in 1919.

The staff on duty around the halls were chatty, helpful and extremely knowledgeable about almost everything on display. Eventually we retired to the café downstairs for some very nice food, well served, again by helpful staff. A good start to the Industrial Heritage season.

Museum of Making front entrance with Peregrine Falcon artwork |

|

|